| 1.6562 | 40NiCrMo8-4 |

1.6562 is high-hardenable steel and susceptible to quench cracking. When the elements that contribute to hardenability is on the high side of their allowable ranges, the upper curve of the hardenability band is virtually a straight line. Thus indicating that 1.6562 would be air-hardened in thin sections. Depending on the precise carbon content, as-quenched hardness ranges from 54 to 59 HRC. Because of high hardenability 1.6562 is not considered suitable for welding by conventional means. Although it can be welded by complicated processes such as electron beam welding. 1.6562 can be formed without difficulty, although its hot strength is considerably higher than that of carbon grades, requiring more powerful forging machines. Machinability is relatively poor

| %C | %Si | %Mn | %P | %S | Cr | Mo | Ni |

| 0.37-0.44 | 0.2-0.34 | 0.7-0.9 | Max 0.02 | Max 0.015 | 0.7-0.95 | 0.3-0.4 | 1.65-2 |

Hot working:

Forging temperature range: 1100-850℃

Note: Heat to 1230 ℃. Do not forge below 850.

Heat treatment:

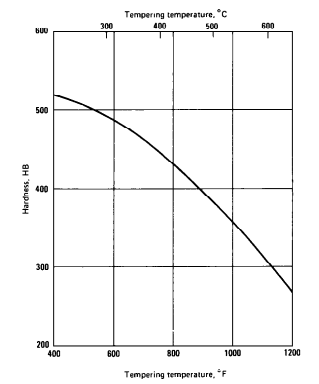

| Normalizing | Annealing. | hardeninig | tempering |

| 870 | 830 | 845 | 600-800 |

Main application:

Structural components for very heavy demands

Shape of product:

Round, flat, step shape, ring, disc, shaft, other shape depend on customer needs