| 1.1221 | C60E |

Multi skilled high-carbon grade. When heat treated, 1.0601 yields a high surface hardness, combined with relatively good toughness. This grade also has good forging characteristics. It is shallow hardening, however, and useful section size is limited. Parts made from it requiring strength is oil quenched; parts requiring high hardness are water quenched

Not recommended for welding.

As-quenched hardness of near65 HRC

After hardening consists of a carbon-rich martensite structure with essentially no free carbide.

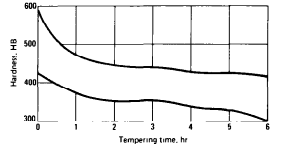

Hardness vs Tempering Time:

Composition:

Composition:

| %C | %Si | %Mn | %P | %S | Cr | Mo | Ni | other |

| 0,57-0,65 | ≤0,40 | 0,60-0,90 | 0,035 | 0,035 | ≤0,40 | 0,10 | ≤0,40 | Cr+Mo+Ni ≤ 0,63 |

Hot working:

Forging temperature range: 1100-850℃

Note: Heat to 1200 ℃. Do not forge below 850.

Heat treatment:

| Soft annealing ℃ | HB 30-soft annealed | Normalizing ℃ | Hardening temperature for quenching in Water ℃ | Hardening temperature for quenching in Oil ℃ | Tempering temperature ℃ |

| 650-700 | 241 | 820-850 | 800-830 | 810-840 | 540-680 |

Main application:

Automobile- and motor construction, mech. engineering

Shape of product:

Round, flat, step shape, ring, disc, shaft, other shape depend on customer needs