| 1.2711 | 5HNM /5XHM |

1.2711 is generally used in the plastic industry. Also, it has good mechanical characteristics (hot and cold)

| %C | %Si | %Mn | %P | %S | %Co | %Cr | %Mo | %Ni | %V | %W | %Ti |

| 0,50-0,60 | 0,15-0,35 | 0,50-0,80 | 0,025 | 0,025 | – | 0,60-0,80 | 0,25-0,35 | 1,50-1,80 | 0,07-0,12 | – | – |

Hot working:

Forging temperature range: 1200-850℃

Note: Heat to 1200 ℃. Do not forge below 850.

Heat treatment:

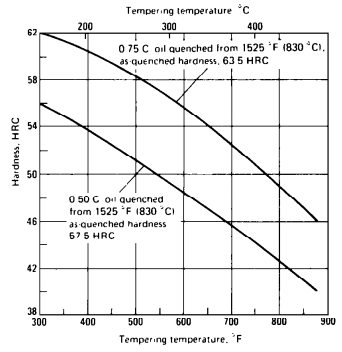

| annealing | Hardness HB30 | hardeninig | tempering | temper hardness(HRC) |

| 660-700 | 225 | 850-880 | 620-700 |

Main application:

Big dies for artificial resin, eventually without subsequent heat-treatment

Shape of product:

Round, flat, step shape, ring, disc other shape depend on customer needs