| 1.6511 | 40XH2MA |

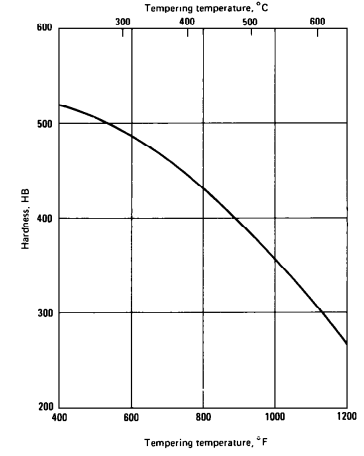

It is normally heat treated by quenching in oil and tempering to the desired hardness. Depending on the precise carbon content, as-quenched hardness ranges from 54 to 59 HRC.

Composition:

| %C | %Si | %Mn | %P | %S | Cr | Mo | Ni | other |

| 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | Max0.025 | Max0.025 | 0.6-0.9 | 0.15-0.25 | 1.25-1.65 | Cu;max0.3 |

Hot working:

Forging temperature range: 1230-850℃

Note: Heat to 1230 ℃. Do not forge below 850.

Heat treatment:

| Soft annealing ℃ | Normalizing ℃ | Hardening temperature ℃ |

| 590-660 | 845-900 | 830-855 |

Main application:

Structural components for heavy demands

Shape of product:

Round, flat, step shape, ring, disc, shaft, other shape depend on customer needs