| 1.7228 | 50CrMo4 |

This grade is medium-hardenability, chromium-molybdenum steel, which is available as hot worked and cold rolled sheet and strip, and hot worked and cold finished bar and rod. This grade is used primarily for gears and other parts requiring fairly high hardness, as well as strength and toughness.

Composition:

| %C | %Si | %Mn | %P | %S | Cr | Mo | Ni | other |

| 0,46-0,54 | ≤0,40 | 0,50-0,80 | 0,035 | 0,035 | 0,90-1,20 | 0,15-0,30 | – | – |

Hot working:

Forging temperature range: 1220-850℃

Note: Heat to 1220 ℃. Do not forge below 850.

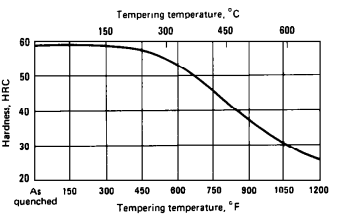

Heat treatment:

| Soft annealing ℃ | HB 30-soft annealed | Normalizing ℃ | Hardening temperature for quenching in Water ℃ | Hardening temperature for quenching in Oil ℃ | Tempering temperature ℃ |

| 680-720 | 248 | 840-880 | 820-850 | 830-860 | 540-680 |

Main application:

Bushes, arbors, control components, links

Shape of product:

Round, flat, step shape, ring, disc, shaft, other shape depend on customer needs