| 1.1133 | 20Mn5 |

1.1133 exhibit fair machinability, fair to good weldability, and excellent cold formability. Cold drawing markedly increases the tensile strength of this grade. The higher manganese content of 1.1133 steel makes this steel more likely to meet required specifications for heat treatment and better adapted for use in larger sections

Composition:

Composition:

| %C | %Si | %Mn | %P | %S | Cr | Mo | Ni | other |

| 0,17-0,23 | 0,60 | 1,00-1,50 | 0,035 | 0,030 | ≤0,40 | – | – | Al 0,015-0,050 |

Hot working:

Forging temperature range: 1260-850℃

Note: Heat to 1260 ℃. Do not forge below 850.

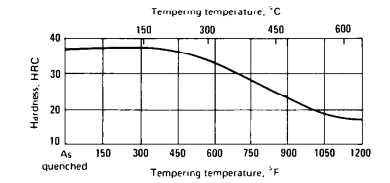

Heat treatment:

| Soft annealing ℃ | HB 30-soft annealed | Normalizing ℃ | Hardening temperature for quenching in Water ℃ | Hardening temperature for quenching in Oil ℃ | Tempering temperature ℃ |

| 650-700 | – | 850-880 | 820-850 | 830-860 | 550-660 |

Main application:

Arbors and discs of large cross section

Shape of product:

Round, flat, step shape, ring, disc, shaft, other shape depend on customer needs